IR speed sensor is an innovative devices that can measure the speed or velocity of an object without physically touching it. Lets check out detailed about how its work, pin configuration and arduino based project also.

Introduction to Infrared Speed Sensor

Infrared sensors are widely used in different industries, such as automotive manufacturing, aerospace, food and beverage, and material handling, among others. The reason behind their popularity is their high accuracy, fast response time, and capability to work effectively in challenging environments.

IR speed sensors serve various applications, including speed monitoring and control, quality control, preventative maintenance, and equipment optimization. They play a significant role in enhancing workplace safety and reducing operating costs, making them an essential component in modern industrial automation systems.

Overall, IR speed sensors are a reliable, accurate, and efficient solution for speed detection and monitoring in various industries. They help businesses improve their operations and achieve greater productivity.

How Does an IR Speed Sensor works?

IR speed sensors work on the principle of infrared light reflection. These sensors have two main components, an infrared emitter and a detector, which emit a beam of infrared light towards the moving object.

When the infrared light strikes the object, it reflects back towards the sensor, and the detector measures the amount of reflected light. By calculating the time it takes for the reflected light to travel back to the sensor, these sensors accurately determine the speed of the object.

This speed is then displayed on the sensor or sent to a monitoring system. It allows the speed of the object to be tracked and controlled. IR speed sensors are commonly used in various Indian industries for quality control, workplace safety enhancement, and speed monitoring and control.

The accuracy of the speed measurement depends on various factors, such as the quality of the sensor and the distance between the object and the sensor. It is essential to ensure that the object is close enough to the sensor to obtain an accurate measurement.

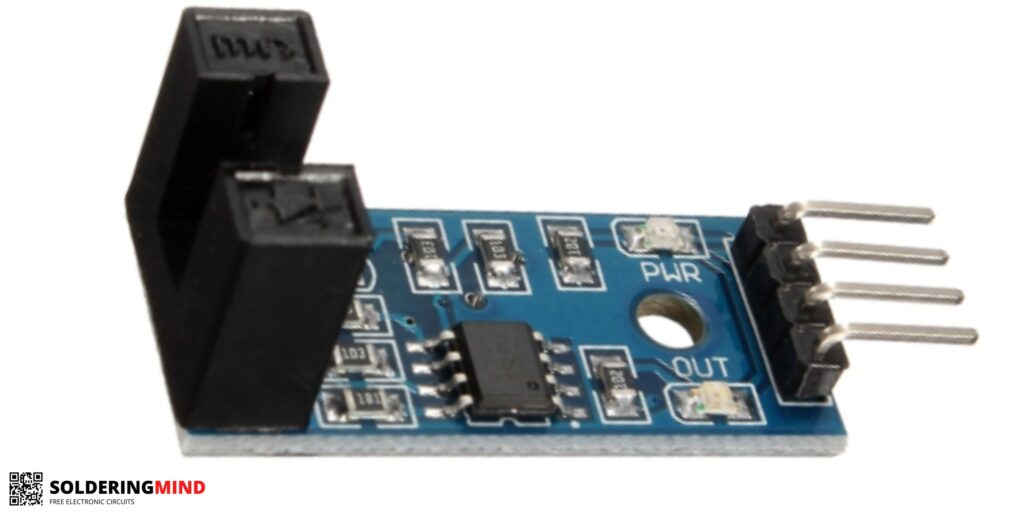

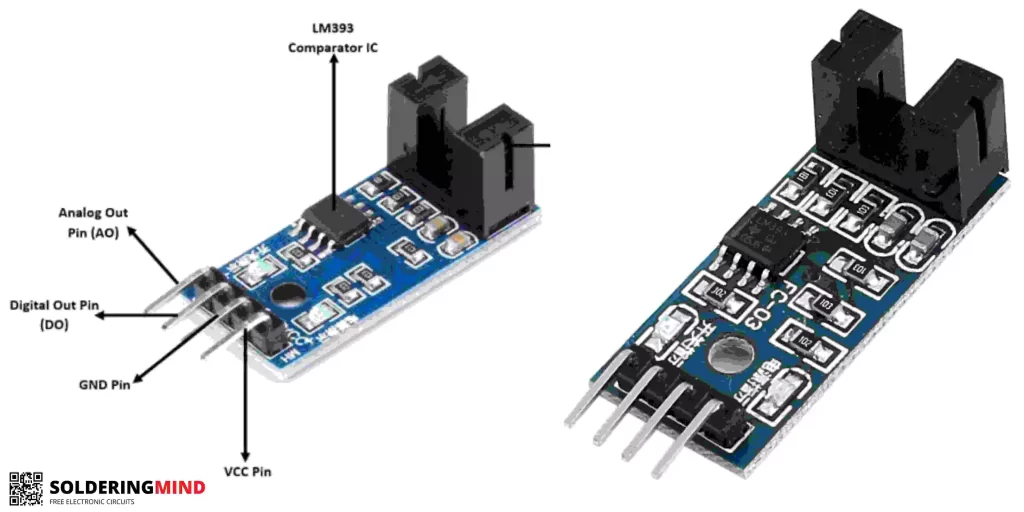

IR Speed Sensor Pin Configuration

There is 4 pins are available on the infrared speed sensor module. With the connections of A0, D0, Gnd and Vcc.

| Pin Name | Description |

|---|---|

| VCC | This pin is used to supply power to the sensor. The recommended voltage range is usually between 3-5 volts. |

| GND | This is the ground pin of the sensor and is used to complete the circuit. |

| OUT | This is the output pin of the sensor, and it provides a digital signal that is proportional to the speed of the object. The output signal can be used for speed monitoring, control, and other applications. |

Factors Affecting the Accuracy of IR Speed Sensors

- Distance between the sensor and the object: The accuracy of IR speed sensors decreases as the distance between the sensor and the object being measured increases. This is because the amount of infrared light reflected by the object decreases as the distance between them increases, which can lead to inaccurate speed measurements.

- Surface finish of the object: The surface finish of the object being measured can also impact the accuracy of IR speed sensors. Rough or uneven surfaces can scatter the infrared light, which can lead to inaccurate speed measurements.

- Angle of incidence: The angle at which the infrared light hits the object being measured can also impact the accuracy of IR speed sensors. If the angle of incidence is too steep, the reflected light may not be detected by the sensor, leading to inaccurate speed measurements.

- Ambient lighting conditions: Ambient lighting conditions, such as bright sunlight or artificial lighting, can interfere with the infrared light emitted by the sensor, leading to inaccurate speed measurements.

- Sensor quality and calibration: The accuracy of IR speed sensors also depends on the quality of the sensor and its calibration. Poor quality sensors or improperly calibrated sensors can lead to inaccurate speed measurements.

Applications of IR Speed Sensors

Infrared (IR) speed sensors are versatile devices with a wide range of applications in various industries.

They are commonly used in industrial automation systems, the automotive and aerospace industries, robotics, medical equipment, and sports and fitness.

For industrial automation, IR speed sensors are used to monitor the speed of machinery such as conveyor belts, motors, and turbines.

In the automotive industry, these sensors can measure the speed of engine flywheels, driveshafts, and wheels to monitor vehicle performance.

In the aerospace industry, IR speed sensors can monitor the speed of aircraft engines and other components for maintenance purposes.

In robotics, IR speed sensors help ensure that robotic arms and other moving components are operating at the desired speed.

while in medical equipment such as centrifuges and blood analyzers, they measure the speed of rotating components for accurate test results.

IR speed sensors can even be used in sports and fitness to monitor an athlete’s speed during activities like cycling and running.

Conclusion

IR speed sensors play a critical role in monitoring the speed of moving components in various industries, such as automation, automotive, aerospace, robotics, and medical equipment.

Their reliability and accuracy are essential for ensuring optimal performance and achieving desired outcomes.

As the demand for automation continues to grow, the use of IR speed sensors is expected to increase as well.

Other Electronics Modules Related Projects

📌 How to use vibration sensor with arduino

📌 Connect Rotary Encoder to an arduino