Are you facing this issue of your Soldering iron not heating up. Their are more reasons to not working or not heating up the soldering iron. So let we see this most common reasons and its solution to heating up your soldering iron again. First of all you need to know about how a soldering iron is working and also what is present inside of the soldering iron, Lets check.

Also Check : Through Hole soldering Tutorial

Soldering iron is an electronic / electrical device that can be used to solder the Lead to the electronics boards or the surface of any copper plates. The soldering iron start to heat after plugin to the alternating current AC. The technical term of soldering iron working is very easy to understand, You all are know about the function of old water heater rods. If you are hearing in first time, i will explain a little bit. The water heater or the water heating rod also contains tungsten coin wounded on the metallic rod.

The tungsten wires has the property of high resistance and durability. In old bulbs the tungsten is used as the filament to get light. Those produce high level of heat and also light. The tungsten coil is wounded on the metallic foil or rod. The more turns of the coil means more resistance to pass the electricity. The one end is connected to the phase and another one is connecting to the neutral. In that time the circuit get complete and the electricity passes through the coil. When the electricity passing through this coil it gets heat up. This is applied on the soldering iron and also the water heater devices. Any problems occurring inside or outside of the soldering iron may stop working or stops heating up.

Why soldering iron not heating up

- The most common reasons of soldering iron is not heating up are listed below. The exact solution also attaching with the problems.

Reason 1: Lower voltage

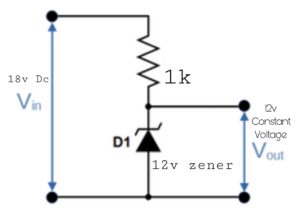

Most of the electrical and electronic devices are working with AC voltage rating of 220V with 50Hz. The soldering iron will provide maximum heat output at the time of stable electric voltage. If the required AC voltage is not get by the coil inside of soldering iron, takes too much time to heat or not heating very well, so avoid soldering when the voltage is below 200v AC.

In this low voltage time keep your inverter ready to use. The inverter can deliver constant voltage rate, this enough to do work with your soldering iron. Take an extension from the inverter ac supply and connect your soldering iron on it. Continue work without any angry.

Reason 2 : Broken wire of soldering iron

The most common reason is soldering iron wire problems, after long usage of soldering iron may cause the damage in wires. Unusual bending or stretching of wire may cause internal disconnection of copper connection between wires. This will lead to the disconnection of soldering iron from the main power supply. Some time this may cause accidental fire of short circuit of both internal wires.

To solve this issue replace the AC cord. Before changing the AC, test the wire is working properly or not. Test the continuity of the wire using a multimeter to verify the issue. If the beep sound is not producing the multimeter means wires disconnected internally or damage occurs inside, so without any doubt change the AC cord.

Also Check This : Rewinding ATEX transformer for making inverter

Reason 3 : Internal coil problem

If the internal coil of the soldering iron get burns or damaged, will cause permanent damage of your soldering iron. If it happens the soldering iron won’t heating up. This can be happened due to the over voltage or poor quality of the soldering iron.

To solve this problem replace the heating coil of soldering iron. You can easily replace it by removing the screws of the soldering iron and detach the connecting wire. Then replace the new purchased heating coil.

Also check this : Buy high quality soldering iron coil