Learn about the important role of capacitor in sealing fan, how it works, its importance and what factors to consider when selecting the right capacitor for optimal performance and longevity of your sealing fan. A capacitor provides necessary starting torque to the fan motor, ensures smooth start up, improves efficiency and ensures reliability.

Sealing fans are an essential component in many industrial and commercial settings, as they help to control the temperature and airflow within a space. These fans are used in a wide range of applications, including HVAC systems, manufacturing plants, and warehouses. They work by blowing air into or out of a space, creating a flow of air that helps to circulate heat and moisture, and remove pollutants and odors.

However, for a sealing fan to function properly, it requires a reliable and efficient motor. The motor is the heart of the fan, and it is responsible for turning the fan blades and creating airflow. One important component that plays a crucial role in the operation of a sealing fan motor is the capacitor. This article will discuss the role of capacitor in sealing fan, how it works, its importance, and what factors to consider when selecting a capacitor.

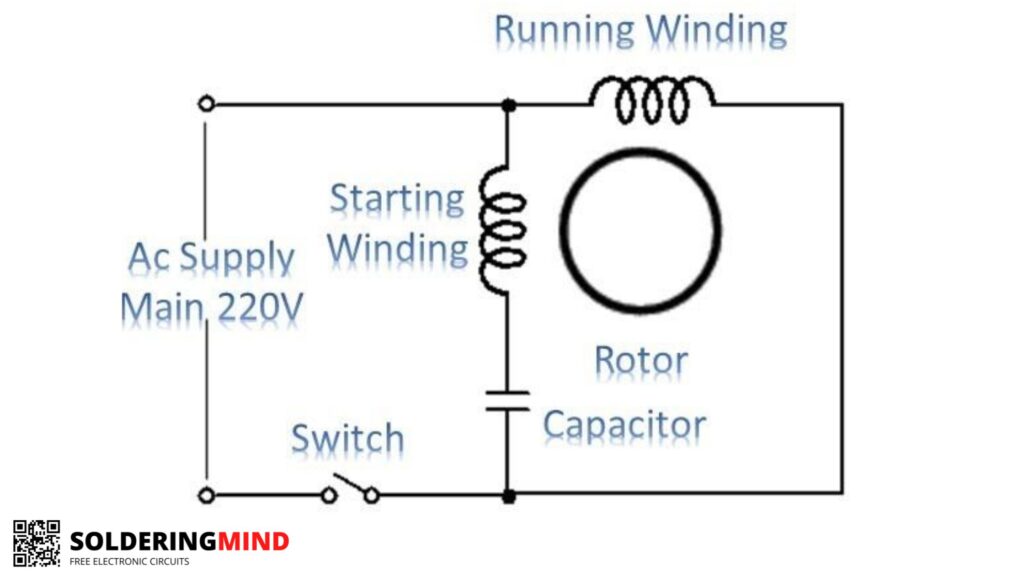

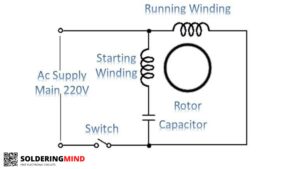

Ceiling Fan Capacitor Connection Circuit

How Capacitor Works in ceiling Fan

In a sealing fan, a capacitor is used to provide the necessary starting torque to the fan motor. A capacitor is an electrical component that stores and releases electrical energy. It works by storing a charge of electrical energy on two metal plates, called electrodes, that are separated by an insulating material. The amount of energy stored in a capacitor is determined by its capacitance, which is measured in microfarads (μF).

When the fan is turned on, the motor initially requires a large amount of energy to start rotating, but once it is running, it requires less energy to continue running. To provide this initial boost of energy, the capacitor releases the stored electrical energy to the motor, providing the necessary starting torque. The result is that the fan motor starts up quickly and smoothly.

The capacitor’s role is to help the motor overcome the “inertia” of the fan blades and get them moving. Without a capacitor, the fan may struggle to start or may even stall, which can lead to damage or breakdowns.

It’s important to note that once the fan is running, the capacitor is no longer needed and the fan motor runs on the power supplied by the AC line. The capacitor is only needed to provide the initial starting torque and it is disconnected or bypassed once the fan is running.

Importance of Capacitor in ceiling Fan

The capacitor plays a vital role in the operation of a sealing fan motor. It helps to provide the necessary starting torque to the fan motor and ensures that the fan starts up quickly and smoothly. The importance of a capacitor in a sealing fan can be summarized as follows:

- Overcoming Inertia: A capacitor helps the fan motor overcome the inertia of the fan blades and get them moving, allowing the fan to start up quickly and smoothly. Without a capacitor, the fan may struggle to start or may even stall, which can lead to damage or breakdowns.

- Preventing Damage: A capacitor helps to protect the fan motor and other components of the fan from damage or breakdowns. A fan that struggles to start or stalls can cause damage to the motor, bearings, and other components, leading to costly repairs or replacements.

- Improving Efficiency: A capacitor helps to improve the efficiency of the fan motor. A fan that starts up quickly and smoothly uses less energy and generates less heat, which can extend the life of the motor and reduce energy costs.

- Ensuring Reliability: A capacitor is an essential component for ensuring the reliability of a sealing fan. Without a capacitor, the fan may not start or may stall frequently, which can lead to frequent repairs and downtime.

Selecting the Right Capacitor

Selecting the right capacitor for a sealing fan is important to ensure optimal performance and prevent damage or breakdowns. The size and type of capacitor used in a sealing fan will depend on the specific requirements of the fan motor.

Here are some factors to consider when selecting a capacitor for a sealing fan:

- Capacitance: The capacitance of a capacitor is measured in microfarads (μF) and it determines the amount of energy stored in the capacitor. The capacitance must be sufficient to provide the necessary starting torque for the fan motor. A typical range for a fan motor capacitor is between 5 μF and 50 μF.

- Voltage Rating: The voltage rating of a capacitor must match the voltage supply of the fan motor. A capacitor that is rated for a higher voltage than the fan motor requires can be damaged or may not function properly.

- Temperature Range: Capacitors are rated for a specific temperature range, typically -40°C to +85°C. It is important to select a capacitor that is rated for the operating temperature of the fan.

- Physical Size: The physical size of the capacitor must be compatible with the space available in the fan. Some capacitors are larger than others and may not fit in the fan.

- Safety Standards: Capacitors must meet safety standards, such as UL and CSA, to ensure they are safe to use.

It’s also important to make sure that the capacitor you select is manufactured by a reputable company and has good reviews. It’s always better to invest a little more to get a good quality capacitor that will last longer and perform better.

Conclusion

In summary, a capacitor is crucial for the proper functioning of a sealing fan. It helps to provide the necessary starting torque to the fan motor, ensures the fan starts up quickly and smoothly, prevents damage, improves efficiency and ensures reliability of the sealing fan.

selecting the right capacitor for a sealing fan is essential to ensure optimal performance and prevent damage or breakdowns. It is important to consider factors such as capacitance, voltage rating, temperature range, physical size, and safety standards when selecting a capacitor for a sealing fan.